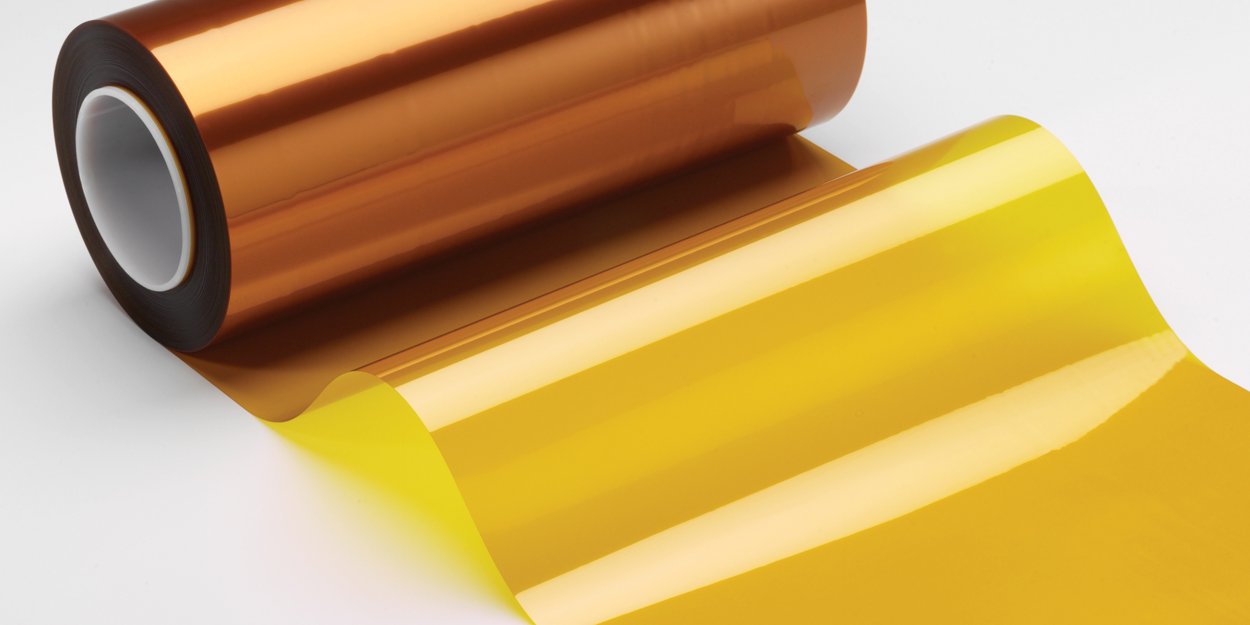

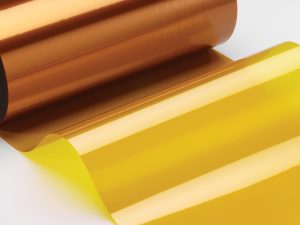

DuPont Kapton FPC polyimide film is treated on both sides and has the same excellent balance of physical, chemical and electrical properties over a wide temperature range offered by general purpose Kapton® HN. Kapton® FPC offers superior dimensional stability and adhesion, and is specifically designed for flex circuit manufacturers.

Adhesion data for FPC can be referenced in the adhesion to Kapton technical bulletin. In applications where superior adhesion and low shrinkage are important, Kapton® FPC is the polyimide film of choice.

APPLICATIONS

• Flexible printed circuits

• Automotive

• Computers

• Consumer products

• Telecommunications equipment

• Industrial instrumentation and controls

• Military applications

• Aerospace

• Electronic parts

• PCB stencils

• Screen printing

• Insulation tubing

PRODUCT SPECIFICATIONS

Kapton FPC is manufactured, slit and packaged according to the product specifications listed in H-38479-11 (6/18).

CERTIFICATION

Kapton FPC meets IPC 4202B requirements.

DIMENSIONAL STABILITY

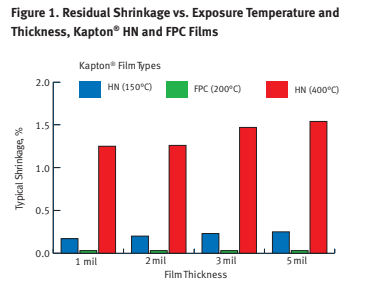

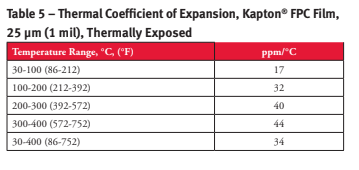

The dimensional stability of Kapton® polyimide film depends on two factors–the normal coefficient of thermal expansion and the residual stresses placed in the film during manufacture. The latter causes Kapton® to shrink on its first exposure to elevated temperatures as indicated in the bar graph in Figure 1. Once the film has been exposed, the normal values for the thermal coefficient of linear expansion as shown in Table 5 can be expected.

Warranty for Kapton products

• Only applies to Dupont products distributed genuine in Vietnam.

• All Kapton products are warranted if the machine fails due to manufacturer fault.

• For warranty and product maintenance, please contact Achilles, customer service phone number: (Mr. Phong – 0913 22 33 81)

• Achilles is the genuine supplier of products related to Kapton

• For retail/whole sale pricing, bulk ordering and product information advice please contact (Mr. Phong – 0913 22 33 81) via info@achilles.com.vn or the website https://achilles.com/.

Tiếng Việt

Tiếng Việt

Reviews

There are no reviews yet.