NOMEX Type 411 is the uncalendered precursor of NOMEX® Type 410. It is available in five thicknesses (0.13 to 0.58 mm) (5 to 23 mil), with a density of 0.3 and correspondingly lower electrical and mechanical properties. It is used in applications such as motor phase insulation and transformer coil end filler, where high bulk and conformability are of prime importance. NOMEX® Type 411 offers increased impregnability and saturability when compared to NOMEX® Type 410, making it suitable for use in cast resin applications as turn and layer insulation.

Electrical properties

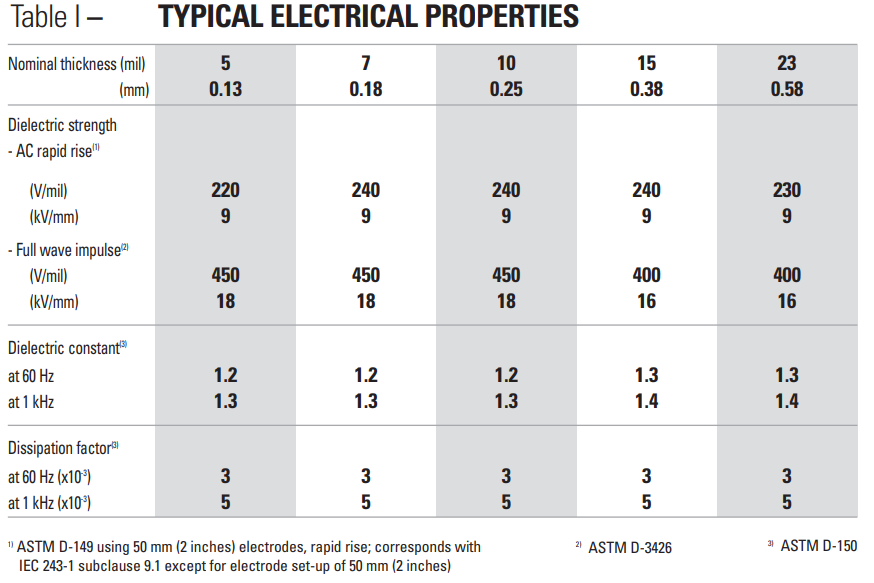

The typical electrical property values for NOMEX® Type 411 paper are shown in Table I. The AC Rapid Rise dielectric strength data of Table I, representing voltage stress levels, withstood 10 to 20 seconds at a frequency of 60 Hz. These values differ from long-term strength potential. DuPont recommends that continuous stresses in transformers not exceed 1.2 kV/mm (30 V/mil) to minimize the risk of partial discharges (corona). The Full Wave Impulse dielectric strength data of Table I were generated on flat sheets, such as in layer and barrier applications. The geometry of the system has an effect on the actual impulse strength values of the material. The dielectric strength data are typical values and not recommended for design purposes. Design values can be supplied upon request.

The effects of temperature on dielectric strength and dielectric constant are shown for NOMEX® Type 410 paper in Figure 1 of the NOMEX® Type 410 data sheet. Since NOMEX® Type 411 paper is identical in chemical composition to NOMEX® Type 410, its electrical properties will react similarly to temperature changes up to and including 220°C. The insensitivity of the dielectric strength of NOMEX® papers to moisture (humidity) has been shown for NOMEX® Type 410 paper in Table II of the NOMEX® Type 410 data sheet. This also holds true for NOMEX® Type 411 paper. Although NOMEX® Type 411 papers exposed for 6 days at 96% relative humidity absorb up to 16% water, they retain at least 85% of their bone-dry dielectric strength. This is

in marked contrast to most porous insulations.

Mechanical properties

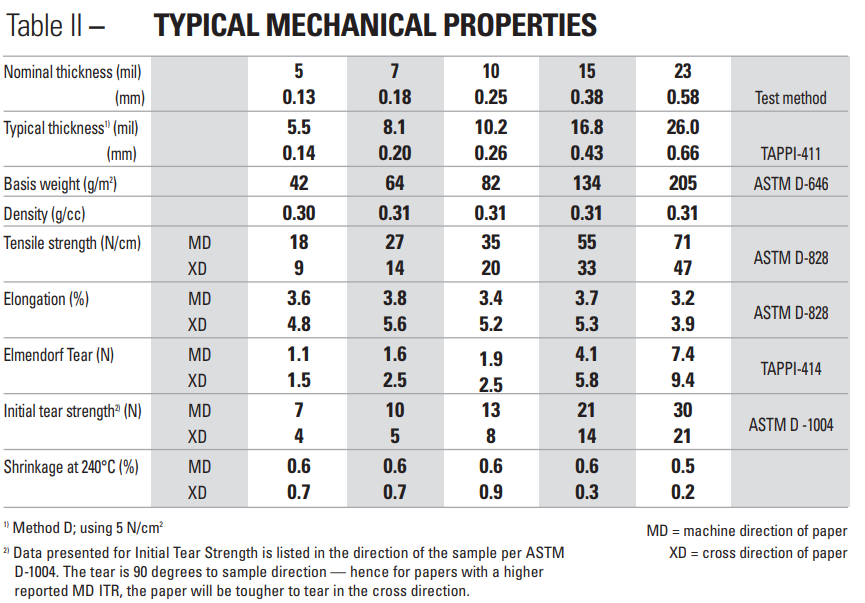

The typical mechanical property values for NOMEX® Type 411 paper are shown in Table II. The effects of temperature on tensile strength and elongation are illustrated for NOMEX® Type 410 paper in Figure 5 of the NOMEX® Type 410 data sheet. The effects of short-term exposure to temperatures up to and including 220˚C will be similar for NOMEX® Type 411 paper. In addition, however, the tensile strength of NOMEX® Type 411 can be significantly increased through heat-treatment under certain specific conditions.

Thermal properties

Arrhenius plots of thermal aging behavior for NOMEX® are exemplified by Figures 7, 8 and 9 of the NOMEX® Type 410 data sheet. Similar aging of NOMEX® Type 411 paper at elevated temperatures has resulted in its recognition as a 220˚C insulating material.

Please note:

The properties in this data sheet are typical, or average values and should not be used as specification limits. Unless otherwise noted, all properties were measured in air under “standard” conditions (in equilibrium at 23˚C, 50% relative humidity). Note that, like other products of papermaking technology, NOMEX® papers have somewhat different properties in the papermaking machine direction (MD) compared to the cross direction (XD). In some applications it may be necessary to orient the paper in the optimum direction to obtain its maximum potential performance

Chemical stability

The compatibility of NOMEX® paper and pressboard with virtually all classes of electrical varnishes and adhesives (polyimides, silicones, epoxies, polyesters, acrylics, phenolics, synthetic rubbers, etc.), as well as other components of electrical equipment, is demonstrated by the many UL-recognized systems comprising NOMEX,® as well as longstanding commercial experience. NOMEX® papers are also fully compatible (and in commercial use) with transformer fluids (mineral and silicone oils and other synthetics), lubricating oils and refrigerants used in hermetic systems. Common industrial solvents (alcohols, ketones, acetone, toluene, xylene) have a slight softening and swelling effect on NOMEX® Type 411 paper, similar to that of water. These effects are largely reversible when the solvent is removed.

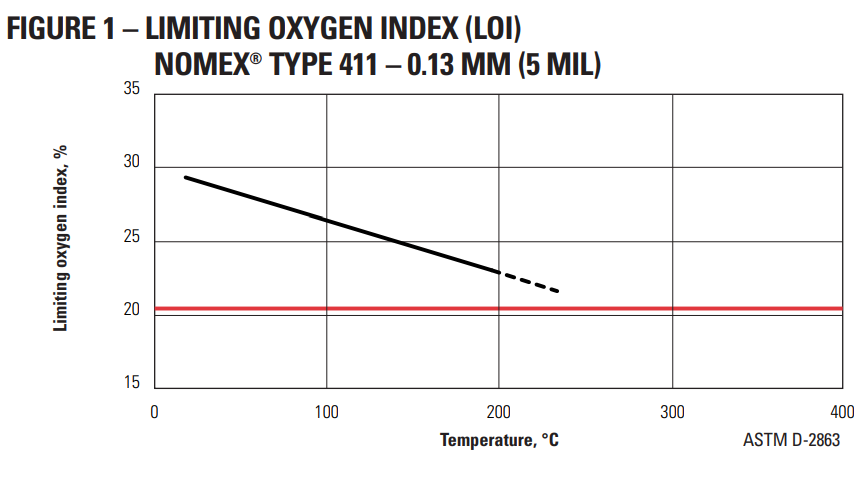

The Limiting Oxygen Index (LOI) of NOMEX® Type 411 – 0.13 mm (5 mil) paper at room temperature is 28.5%, and is 21.8% at 220˚C. Materials with LOI above 20.8% (ambient air) will not support combustion. NOMEX® Type 411 – 0.13 mm (5 mil) must be heated to above 240˚C before its LOI declines below the flammability threshold, as is shown in Figure 1. NOMEX® Type 411 paper offers improved saturability of varnishes and resins versus NOMEX® Type 410 paper due to its more open structure.

The exact amount of improvement depends on the specific varnish, application technique, and product thickness. In one test, with hand-dipped varnish, this resulted in a 40% saturability improvement of NOMEX® Type 411 versus NOMEX® Type 410, whereas with vacuum-pressure impregnation, the saturability improvement was as high as 200%.

Tiếng Việt

Tiếng Việt

Reviews

There are no reviews yet.