For Semiconductor Dielectric Etch Applications

Product Description

DuPont™ Kalrez® 9300 perfluoroelastomer parts are a brown product for Dielectric (Oxide) Etch applications. It has been specifically designed for use in applications where the plasma environment is a combination of ions (“physical”) and radicals (“chemical”), i.e., where a balance of “physical” and “chemical” plasma erosion resistance is typically required.

DuPont™ Kalrez® 9300 perfluoroelastomer parts are a brown product for Dielectric (Oxide) Etch applications. It has been specifically designed for use in applications where the plasma environment is a combination of ions (“physical”) and radicals (“chemical”), i.e., where a balance of “physical” and “chemical” plasma erosion resistance is typically required.

Typical Physical Properties

| Color |

Brown |

| Hardness, Shore A (plied slabs) (test method ASTM D2240) |

77 |

| Hardness, Shore M (O-ring) (test method ASTM D2240 & D1414) |

82 |

| 100% Modulus, MPa (psi) (test method ASTM D412) |

6.13 (889) |

| Tensile Strength at Break, MPa (psi) (test method ASTM D412) |

15.43 (2238) |

| Elongation at Break (%) (test method ASTM D412) |

222 |

| Compression Set, %70 hrs.at 204°C (400°F) (test method ASTM D395B & ASTM D1414) |

25 |

| Compression Set, %70 hrs.at 250°C (482°F) (test method ASTM D395B & ASTM D1414) |

37 |

| Compression Set, %70 hrs.at 300°C (572°F) (test method ASTM D395B & ASTM D1414) |

56 |

| Maximum Service Temperature °C(°F) |

300 (572) |

Features/Benefits

• Low erosion rate and ultra-low particle generation in ion/radical dominant oxygen and fluorine-based plasmas

• Excellent resistance to etch process chemistry

• Very low metals content

• Excellent thermal stability

• Excellent mechanical strength

Suggested Applications

• Gas inlet/orifice seals

• Chamber lid seals

• Isolation valve seals

• Bonded gate valves/slit valve door seals

Plasma Weight Loss

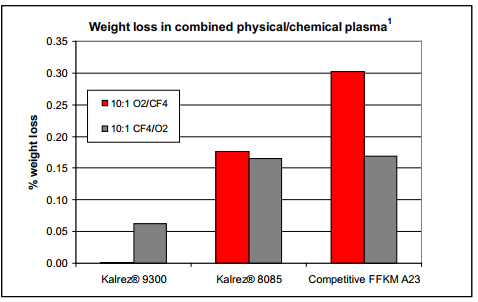

Because there is no industry standard to characterize elastomer plasma resistance, OEMs and Fablines rely on in-use testing and actual performance. To further assist the industry in proper seal selection, DuPont has developed a test method that closely approximates chamber conditions to quantify seal resistance to plasma. In this test on weight loss, O-rings are placed on a silicon wafer and directly exposed to extremely damaging plasma environments. Kalrez® 9300 parts exhibited lower weight loss upon exposure to combined ion and radical oxygen and fluorine-based plasma versus Kalrez® 8085 parts and competitive FFKM A23.

Warranty for Kalrez products

• Only applies to Dupont products distributed genuine in Vietnam.

• All Kalrez products are warranted if the machine fails due to manufacturer fault.

• For warranty and product maintenance, please contact Achilles, customer service phone number:098 469 4884(Ms. Duc).

• Achilles is the genuine supplier of products related to Kalrez DuPont.

• For retail/whole sale pricing, bulk ordering and product information advice please contact 098 469 4884(Ms. Duc) via info@achilles.com.vn or the website https://achilles.com/.

Tiếng Việt

Tiếng Việt

Reviews

There are no reviews yet.