Optimal Seal Performance and Lower Cost of Ownership for Semiconductor Applications

To transform raw semiconducting materials into a useful device requires hundreds of chemical processing steps. A significant number of these steps involve aggressive acids, solvents, and bases (including amines) used to clean, rinse, etch or strip unwanted materials and contaminants from the wafer surface. These chemicals can attack elastomeric seals causing them to swell and degrade or to leach undesirable

metallic and ionic extractables that affect integrated circuit functionality.

The trend toward larger wafers, smaller feature size, and decreasing thickness of deposited layers has placed increased emphasis on the need to minimize or eliminate sources of process contamination. Chemical and equipment manufacturers go to great lengths to minimize the potential for contamination that could result in chip defects.

DuPont has developed a number of products that resist chemical attack and are formulated and processed to minimize the potential for undesirable contaminants. The newest addition to our product line, DuPont™ Kalrez® 6375UP, has an excellent balance of performance characteristics required for semicon wet processing environments.

| Process Type | Typical Chemicals | Temp. Range, °C | DuPont™ Kalrez® 6375UP | DuPont™ Kalrez® 4079UP | DuPont™ Kalrez® 1050UP |

| Wafer Prep, Cleaning, and Rinsing |

UPDI, Ozonated DI H20 TCE, IPA, Acetone Piranha, SC-1, SC-2 HF (49%), O3 |

25-125 | Suggested Compound | Suitable Alternate | Consult DuPont |

| Wet Etching |

HNO3/HF/H20 H3PO4/HNO3/Acetic/H20 H3PO4/HNO3/HF/H20,H3PO4 |

25–180 | Suggested Compound | Suitable Alternate | Consult DuPont |

| Photolithography Developing, Stripping, Rinsing | H2SO4 + Oxidant Organic Acids Chromic/Sulfuric Acid | 25–125 | Suggested Compound | Suitable Alternate | Consult DuPont |

|

NaOH, TMAH Xylene, Stoddard Solvent nMP |

25–125 | Suggested Compound | Suitable Alternate | Consult DuPont | |

|

NMP/Alkanolamine DMSO/MEA DMAC/DEA Hydroxylamine |

25–125 | Suggested Compound | Consult DuPont | Suitable Alternate | |

| Copper Plating |

CuSO4 Solution H2SO4, H2O2 UPDI, Citric Acid |

25–100 | Suggested Compound | Suitable Alternate | Consult DuPont |

Note: Product ratings are based on a combination of chemical resistance and extractable performance. In applications where extractables are not a critical concern, multiple products may be appropriate. For further assistance, contact DuPont and ask to speak with a Kalrez® Applications Engineer.

DuPont™ Kalrez® Offers Excellent Resistance to Chemical Attack

For many applications, low volume swell of elastomers is critical for proper equipment operation. Excessive swell may cause permanent seal failure due to equipment hang-up, extrusion, etc. While other physical property testing may be needed to adequately define product performance in a particular application, volume swell is an excellent indicator of resistance to chemical attack. The following data represents a summary of internal and external compatibility tests performed to determine the volume swell of products suggested for semiconductor wet process environments.

| Immersion Chemistry | Exposure Conditions | Volume Swell | ||

| DuPont™ Kalrez® 6375UP | DuPont™ Kalrez® 4079UP | DuPont™ Kalrez® 1050UP | ||

| UPDI Water

Piranha SC-1 SC-2 49% HF Ammonium Hydroxide |

85 °C, 30 days

25 °C, 30 days 25 °C, 30 days 25 °C, 30 days 25 °C, 30 days 100 °C, 7 days |

0.7

0.1 0.6 0.1 2.8 2.6 |

2.3

0.1 1.1 0.1 0.6 9.8 |

5.5

0.1 0.6 0.2 1.8 Not Tested |

| Sulfuric Acid (H2SO4)

Nitric Acid (HNO3) Phosphoric/Acetic/Nitric Acid Hydrofluoric Acid/HNF4 Hydrochloric, Nitric Acid and H2O |

120 °C, 30 days

85 °C, 7 days 60 °C, 28 days 60 °C, 28 days 60°C, 28 days |

1.3

2.1 1.0 0.0 5.0 |

0.8

1.5 1.0 1.0 6.0 |

2.8

Not Tested Not Tested Not Tested Not Tested |

| n-Methylpyrrolidone

Dimethyl Acetamide |

80 °C, 7 days

80 °C, 7 days |

2.0

2.4 |

2.4

4.0 |

3.2

4.4 |

| ACT 690C

ACT-NP870 ACT 935 ACT NE-14 ACT CMI |

95 °C, 10 days

80 °C, 10 days 80 °C, 10 days 25 °C, 10 days 80 °C, 10 days |

1.5

2.0 1.6 0.0 2.7 |

7.9

6.2 5.1 0.0 6.5 |

2.0

2.0 1.8 0.3 5.2 |

| EKC265

EKC830 EKC4000 PCT |

75 °C, 7 days

75 °C, 7 days 75 °C, 7 days |

1.0

3.1 0.7 |

2.8

10.0 1.7 |

0.7

10.1 2.5 |

| PRS-1000

PRS-3000 ALEG™310 REZI 28 |

95 °C, 10 days

80 °C, 10 days 80 °C, 10 days 80 °C, 10 days |

1.5

2.0 1.6 2.7 |

7.9

6.2 5.1 6.5 |

2.0

2.0 1.8 5.2 |

* Note: The volume swell values above should be used as an approximate indicator of relative compatibility performance. Generally <10% volume swell is desirable.

Keep Contamination Under Control with Kalrez® Parts

Semiconductor devices are vulnerable to many types of contaminants including trace chemicals (anions and total organic carbons—TOCs), metallic ions, and particles.

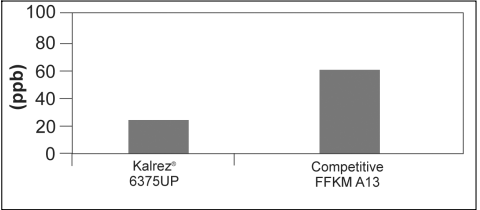

Chemical Contamination (anions and TOCs)

Two of the major sources of contamination in semiconductor processes are trace elements of unwanted chemicals (anions) and organic contaminants (TOCs). Process chemicals and process water can become contaminated and interfere with wafer processing. Chlorine (i.e., chloride ion) is such a contaminant and is rigorously controlled in process chemicals. In UPDI systems, TOCs can adhere to wafer surfaces and adversely affect oxide quality or film quality.

Elastomeric seals can be a source of this contamination. DuPont has developed products to minimize the potential for chemical and organic contamination.

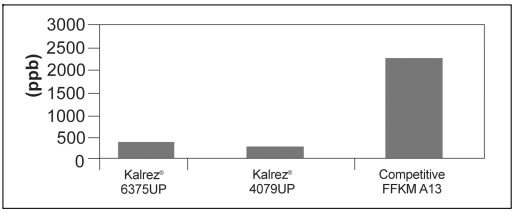

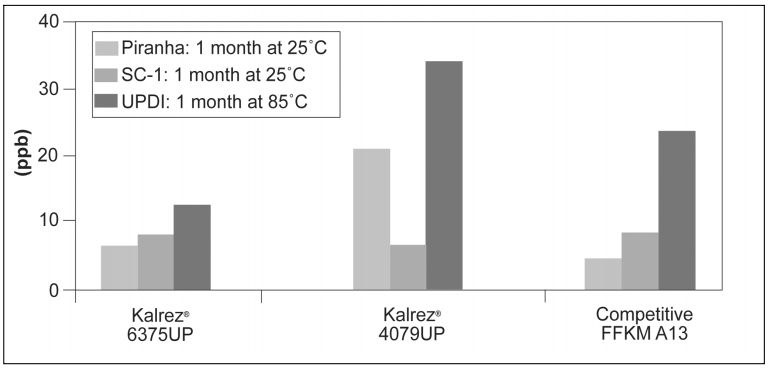

Metallic Ion Contamination

Process chemicals can cause metallic ions to leach out of seal materials. These metallic ions, depending on type and quantity, can alter electrical properties and cause device failure to occur. Below is a summary of total metallic extractables after immersion of O-rings in various cleaning and wafer preparation process chemicals. DuPont™ Kalrez® 6375UP has an excellent balance of chemical resistance and low metallic extractables in a variety of process fluids.

Typical Physical Properties

| Kalrez®Product | Color | Hardness Shore A (pellet) (method ASTM D2240) | Hardness Shore M (O-ring) (method ASTM D2240 & ASTM D1414) | Max. Cont. Service Temp °C | 100%Modulus MPa (method ASTM D412) | Compression Set at 70 hr 204°C, % (method ASTM D395) |

| 6375UP | Black | 75 | 83 | 275 | 7.23 | 25 |

| 4079UP | Black | 75 | 83 | 316 | 7.23 | 25 |

| 1050UP | Black | 82 | – | 288 | 12.40 | 35 |

Warranty for Kalrez products

• Only applies to Dupont products distributed genuine in Vietnam.

• All Kalrez products are warranted if the machine fails due to manufacturer fault.

• For warranty and product maintenance, please contact Achilles, customer service phone number:098 469 4884(Ms. Duc).

• Achilles is the genuine supplier of products related to Kalrez DuPont.

• For retail/whole sale pricing, bulk ordering and product information advice please contact 098 469 4884 (Ms. Duc) via info@achilles.com.vn or the website https://achilles.com/.

Tiếng Việt

Tiếng Việt

Reviews

There are no reviews yet.