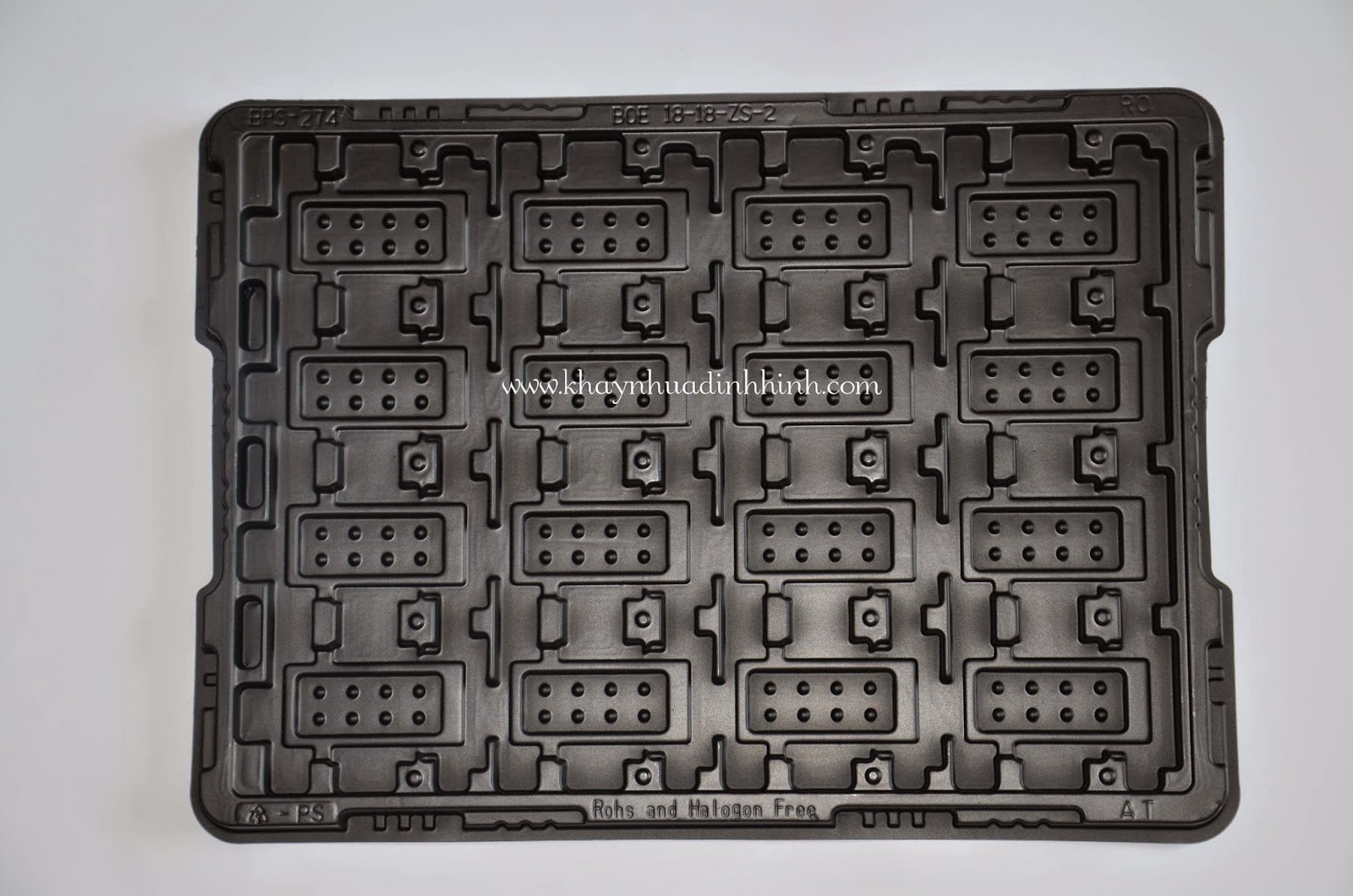

After being assembled, displays and related parts and components for smartphones and tablets are usually transported either within the factories or to another facility. The plastic packaging trays used for this purpose must have antistatic properties as static charges can cause numerous problems. Common on plastic surfaces, these charges can attract dust and cause ESD (electro-static discharge) damage to sensitive electronic components and devices.

Antistatic packaging trays are made by coating plastic sheets (PP,PET,PC… ) with a special Clevios™ formulation.

Clevios™ coatings provide multiple benefits compared to other technologies such as carbon-filled or surfactant-coated trays:

- Wider range of sheet resistance control, 10E4 – 10E10 Ohm/sq

- Highly transparent and clean, ideal for barcode scanning (not possible for carbon-filled materials)

- Stable and permanent antistatic effect at any humidity, unlike surfactants

- Clean: no generation of black particles, as with carbon-filled materials

End Use Segments:

Tiếng Việt

Tiếng Việt