For Semiconductor Processes.

Product Description

DuPont™ Kalrez® 8085 perfluoroelastomer parts are a beige, general purpose product for “select” etch, ash/strip and deposition processes. It has been formulated for minimal particle generation in NF3 plasma. Kalrez® 8085 exhibits very low particle generation and low weight loss in oxygen and fluorine-based plasmas, has excellent mechanical strength and is well-suited for both static and dynamic sealing applications (e.g., bonded slit valve doors, bonded gate valves, bonded pendulum valves, gas orifice seals, gas feedthrough seals, chamber lid seals, etc.) A maximum continuous service temperature of 240 °C is suggested. Kalrez® 8085 can also withstand short-term excursions to 275 °C. Ultrapure post-cleaning and packaging is standard for all Kalrez® 8085 parts.

Typical Physical Properties

| Color |

Beige |

| Hardness Shore A, (pellet) (test method ASTM D2240) |

80 |

| Hardness Shore M (test method ASTM D2240 & ASTM D1414) |

86 |

| 100% Modulus, MPa (psi) (test method ASTM D412) |

|

| Tensile Strength at Break, MPa (psi) (test method ASTM D412) |

16.3 |

| Elongation at Break (%) (test method ASTM D412) |

159 |

| Compression Set, % 70 hr. at 150 °C (test method ASTM D395B & ASTM D1414) |

28 |

| Compression Set, % 70 hr. at 175 °C (phương pháp ASTM D395B & ASTM D1414) |

35 |

| Compression Set, % 70 hr. at 204°C (test method ASTM D395B & ASTM D1414) |

42 |

| Maximum Service Temperature °C (°F) |

240 |

| Max. Excursion Temperature, °C |

275 |

Performance Features/Benefits

• Very low particle generation in NF3 plasma.

• Excellent mechanical strength properties.

• Longer seal life.

• Reduced PM time and increased equipment uptime.

• Lower cost of ownership.

Ứng dụng đề xuất:

• Bonded slit valve door seals.

• Bonded gate valves.

• Chamber lid seals.

• Gas inlet seals.

• Gas orifice seals.

• Gas feedthrough seals.

Fabs Choose Kalrez® 8085 for Improved Performance.

Kalrez® 8085 has been reported to significantly improve wafer production in a variety of semiconductor plasma process applications where oxygen and fluorinated plasmas are used during the cleaning cycle.

In a number of evaluations at fabline customers, Kalrez® 8085 exhibited improved mechanical strength, lower particle generation and longer seal life compared to competitive perfluoroelastomer parts in both static and dynamic sealing applications.

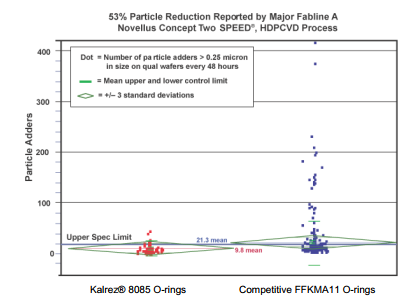

Case Report #3137 — DuPont™ Kalrez® 8085 Reported to Reduce Particle Adders by 53% Over Competitive Perfluoroelastomer (FFKM A11).

• HDPCVD O-ring.

• Process chemistry: Silane.

• Cleaning chemistry: NF3, O2 and O3.

• Competitive FFKM generated significantly more particle adders.

Case Report #4115 — Kalrez® 8085 Extended Seal Life 100% versus Competitive Perfluoroelastomer (FFKM A18)

• PECVD RPS cleaning module O-ring seals.

• Process chemistry: SiH4, O2.

• Cleaning chemistry: NF3.

• Competitive perfluoroelastomer failed due to severe plasma attack, i.e., erosion, cracking, etc.

Case Report #6553 — Kalrez® 8085 Improved Wafer Production over 25% versus Competitive Perfluoroelastomer (FFKM A2)

• PECVD gas box, shower head and plate seal

• Process chemistry: TEOS, O2 at 400 °C

• Cleaning chemistry: NF3 plasma at 3500 watts

• Competitive perfluoroelastomer failed due to cracking and excessive leakage

Case Report #2883 — Kalrez 8085 Extended Seal Life 100% versus Competitive Perfluoroelastomer (FFKM A2)

• Ash isolation valve poppet seal

• Process chemistry: O2, CF4

• Cleaning chemistry: N/A

• Competitive perfluoroelastomer failed due to cracking and excessive leakage

Warranty for Kalrez products

• Only applies to Dupont products distributed genuine in Vietnam.

• All Kalrez products are warranted if the machine fails due to manufacturer fault.

• For warranty and product maintenance, please contact Achilles, customer service phone number:098 469 4884 (Ms. Duc).

• Achilles is the genuine supplier of products related to Kalrez DuPont.

• For retail/whole sale pricing, bulk ordering and product information advice please contact 098 469 4884 (Ms. Duc) via info@achilles.com.vn or the website https://achilles.com/.

Tiếng Việt

Tiếng Việt

Reviews

There are no reviews yet.