DuPont Kalrez MS220 perfluoroelastomer parts are designed for mechanical seals where superior

chemical resistance and low compression set are critical for successful sealing performance.

Kalrez MS220 continues the DuPont tradition of providing high value in use perfluoroelastomer parts to extend equipment mean time between repair (MTBR), while offering an excellent combination of properties (resistance to steam, acids and bases) at temperatures up to 230°C (446°F).

It is an effective alternative to other general purp

Table 1: Typical Physical Properties1

| Color Black | Black |

| Maximum Application Temperature2, °C (°F) | 230 (446) |

| Durometer, Shore A3 | 76 |

| 100% Modulus4, MPa (psi) | 6.93 (1005) |

| Tensile Strength at Break4, MPa (psi) | 15.93 (2310) |

| Elongation at Break4, % | 154 |

| Compression Set5, 70 hr at 204 °C (400 °F) | 24 |

| 00 °F) Low Temperature Sealing2, °C (°F) | -14 (6) |

| Linear Coefficient of Thermal Expansion2, °C (°F) | 3.85 x 10E-4 (2.14 x 10E-4) |

Chemical Resistance

Integrity of seal properties is closely associated with low elastomer swell. Excessive swell may cause seal damage, extrusion, leaks and other failures due to equipment malfunction. Assuming proper seal design, low volume swell can be a reliable predictor of elastomer seal performance in mechanical seal applications.

The following data is the result of lab compatibility testing to determine the volume swell of Kalrez® MS220 parts when exposed to various fluids. The chemicals represent some of the most aggressive substances in industrial applications. Additional physical property testing may be needed to further define product performance.

Because every application is unique, it is strongly recommended that immersion testing be performed in the actual composition of the process fluids.

Table 1: Typical Physical Properties1

| Color Black | Black |

| Maximum Application Temperature2, °C (°F) | 230 (446) |

| Durometer, Shore A3 | 76 |

| 100% Modulus4, MPa (psi) | 6.93 (1005) |

| Tensile Strength at Break4, MPa (psi) | 15.93 (2310) |

| Elongation at Break4, % | 154 |

| Compression Set5, 70 hr at 204 °C (400 °F) | 24 |

| 00 °F) Low Temperature Sealing2, °C (°F) | -14 (6) |

| Linear Coefficient of Thermal Expansion2, °C (°F) | 3.85 x 10E-4 (2.14 x 10E-4) |

Chemical Resistance

Integrity of seal properties is closely associated with low elastomer swell. Excessive swell may cause seal damage, extrusion, leaks and other failures due to equipment malfunction. Assuming proper seal design, low volume swell can be a reliable predictor of elastomer seal performance in mechanical seal applications.

The following data is the result of lab compatibility testing to determine the volume swell of Kalrez® MS220 parts when exposed to various fluids. The chemicals represent some of the most aggressive substances inindustrial applications.

Additional physical property testing may be needed to further define product performance. Because every application is unique, it is strongly recommended that immersion testing be performed in the actual composition of the process fluids.

Table 2: Comparison of Volume Swell* (% Change) between MS220 and nearest competitive FFKM after 672 hours immersion

| Fluid | Temperature °C (°F) | MS220 | Nearest competitive FFKM A-1 |

| Steam | 225 (437) | A – NR | NR |

| Nitric Acid (70%) | 85 (185) | A | C |

| Butyraldehyde, | 70 (158) | B | B |

| Sulfuric Acid (96-98%) | 150 (302) | A | C |

| Glacial Acetic Acid | 100 (212) | A | A |

| Ammonium Hydroxide | 100 (212) | B | B |

| Ethylenediamine | 90 (194) | C | C |

| 1,2 Dichloroethane | 100 (212) | A | NR |

| Methanol | 100 (212) | A | NR |

| Toluen | 100 (212) | A | A |

| HCFC | 25 (77) | A | NR |

*AS568 K214 O-ring test specimens.

Volume swell rating: A= 0-10%, B= 10-20%, C= >20%, NR= No Rating Available

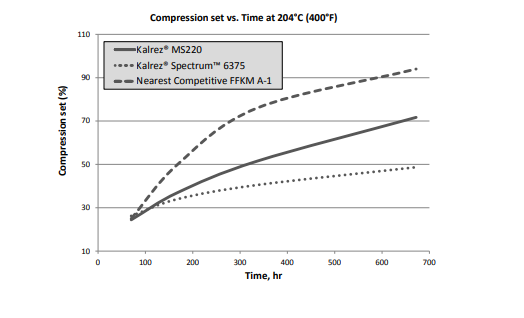

Thermal Resistance

One method of predicting heat resistance is compression set. This is defined as the percentage by which a standard test piece (typically an O-ring or a pellet) fails to return to its original thickness after being subjected to a standard compressive load or deflection and temperature for a fixed period of time. This chart shows some elastomer comparisons with regard to compression set resistance (ASTM D395 Method B).

Warranty for Kalrez products

• Only applies to Dupont products distributed genuine in Vietnam.

• All Kalrez products are warranted if the machine fails due to manufacturer fault.

• For warranty and product maintenance, please contact Achilles, customer service phone number: 098 469 4884 (Ms. Duc).

• Achilles is the genuine supplier of products related to Kalrez DuPont.

• For retail/whole sale pricing, bulk ordering and product information advice please contact 098 469 4884 (Ms. Duc) via info@achilles.com.vn or the website https://achilles.com.vn/

Tiếng Việt

Tiếng Việt

Reviews

There are no reviews yet.