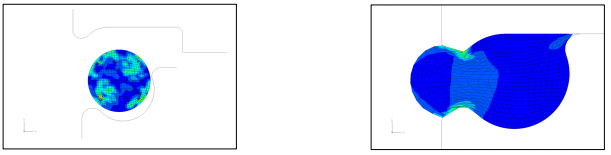

Couplings based on DIN11864-2, Form A, assume complete filling of the groove after compression of the O-ring in order to form a hygienic seal (Figure 1). Exposure of the coupling to various chemicals, cleaning agents, steam and elevated temperatures, can cause the O-ring material to swell, resulting in intrusion of the O-ring into the process stream (Figure 2).

Consequently, a dead space may be formed, leading to contamination and loss of the hygienic properties of the coupling. Additionally, the O-ring may be damaged, break off and contribute to particulates in the process. Some elastomeric compounds, like EPDM and fluoroelastomers, have limited chemical and thermal resistance, especially when exposed to the CIP and SIP cycles being used in today’s pharmaceutical and biopharmaceutical processes.

DuPont Kalrez perfluoroelastomer parts, with their superior chemical resistance, provide materials that can avoid these potential volume swell problems and are being used more often in today’s environments.

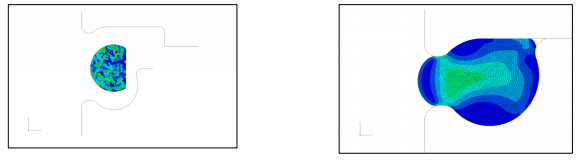

Kalrez® parts, however, do exhibit thermal expansion — a physical property that cannot be avoided and could also lead to intrusion in the process stream. Engineers at DuPont S.A in Geneva created a new design with the help of Finite Element Analysis (FEA). Our design is a D-shape (Figure 3) and precisely sized to create sufficient free volume in the groove.

This allows the Kalrez® part to expand without intrusion into the process stream (Figure 4).

Kalrez parts based on compounds 6230 (black) and 6221 (white) are well suited for these types of designs and couplings and comply with the requirements of U.S. FDA regulation 21 CFR 177.2600 and the extractive requirements of 21 CFR177.2400(d)(1). They have also been tested and in accordance with requirements of a United States Pharmacopeia Class VI testing protocol and meet the requirements of USP Class VI polymer. (see disclaimer on page 2) A major French pharmaceutical company has successfully tested our design.

The photo in Figure 5 shows a typical material that has swollen and taken a permanent deformation after only 10 SIP cycles – the intrusion into the process stream is obvious. Figure 6 shows the DuPont Kalrez design after 22 SIP cycles, where swelling is minimal along with minimal intrusion into the process stream.

Kalrez® perfluoroelastomer seals for DIN11864-2 are available in nominal dimensions DN10, DN15 and DN20. Other dimensions can be made available upon demand.

Warranty for Kalrez products

• Only applies to Dupont products distributed genuine in Vietnam.

• All Kalrez products are warranted if the machine fails due to manufacturer fault.

• For warranty and product maintenance, please contact Achilles, customer service phone number: 098 469 4884 (Ms. Duc).

• Achilles is the genuine supplier of products related to Kalrez DuPont.

• For retail/whole sale pricing, bulk ordering and product information advice please contact 098 469 4884 (Ms. Duc) via info@achilles.com.vn or the website https://achilles.com.vn

Tiếng Việt

Tiếng Việt

Reviews

There are no reviews yet.