For PECVD/ALD/HDPCVD & Conductor Etch Applications

Product Description

DuPont™ Kalrez® 9100 is an amber translucent product targeted specifically for PECVD, ALD, HDPCVD and Conductor (Poly/Metal) Etch applications. Kalrez® 9100 has been specifically designed for low erosion and ultra-low particle generation in harsh plasma environments. It offers excellent thermal stability, very low outgassing as well as excellent elastic recovery and good mechanical strength properties and is well suited for both static and “select” dynamic sealing applications. A maximum application temperature of 300°C (572°F) issuggested. Ultrapure post-cleaning and packaging is standard for all Kalrez® 9100 parts.

Typical Physical Properties

| Color |

Amber translucent |

| Hardness, Shore A (plied slabs) (test method ASTM D2240) |

70 |

| Hardness, Shore M (O-ring) (test method ASTM D2240 & D1414) |

78 |

| 100% Modulus, MPa (psi) (test method ASTM D412) |

5.17 (750) |

| Tensile Strength at Break, MPa (psi) (test method ASTM D412) |

15.67 (2273) |

| Elongation at Break (%) (test method ASTM D412) |

238 |

| Compression Set, %70 hrs.at 204°C (400°F) (test method ASTM D395B & ASTM D1414) |

18 |

| Compression Set, %70 hrs.at 250°C (482°F) (test method ASTM D395B & ASTM D1414) |

21 |

| Compression Set, %70 hrs.at 300°C (572°F) (test method ASTM D395B & ASTM D1414) |

53 |

| Maximum Service Temperature °C (°F) |

300 (572) |

Features/Benefits

• Low erosion rate and ultra-low particle generation in oxygen and fluorine-based plasmas

• Excellent resistance to dry process chemistry

• Excellent thermal stability

• Very low outgassing properties and metals content

• Excellent elastic recovery and low compression set properties

Suggested Applications

• Gas inlet/orifice seals

• Chamber lid seals

• Isolation valve seals

• “Select” bonded gate valves/slit valve door seals

Particle Generation

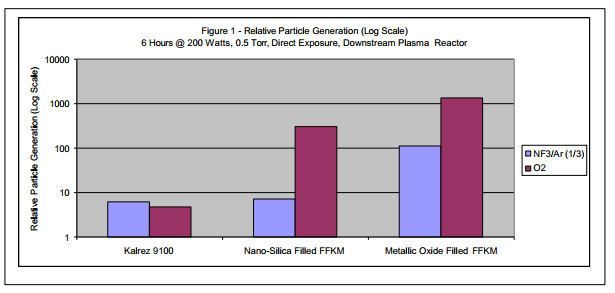

Conventional perfluoroelastomer (FFKM) sealing materials normally contain carbon black and/ormineral fillers. Newer products are either unfilled or formulated with polymeric fillers. Plasma resistance can be significantly different depending on the type of filler used. If the filler has high resistance to plasma, such as BaSO4, TiO2, etc., it can “shield” the polymer to reduce erosion or weight loss, but have the high potential for particle generation by leaving discrete particles behind once the polymer has become etched. Unfilled and polymeric filled products essentially contain no other elements other than carbon, fluorine and oxygen, which can be completely etched to form volatiles, thereby significantly reducing the potential for contamination. Figure 1 shows the relative particle generation of DuPont™ Kalrez® 9100 versus a nano-silica and a metallic oxide filled FFKM product in differentplasmas.

Fabs Choose Kalrez® 9100 For ImprovedPerformance

Kalrez® 9100 has been reported to significantly improve wafer production in a variety of semiconductor process applications where oxygen and fluorinated plasmas are used during the cleaning cycle. In a number of evaluations at fabline customers, Kalrez® 9100 exhibited less erosion, lower particle generation and longer seal life compared to competitive perfluoroelastomers in both static and dynamic sealing applications.

Case Report #5903 — PM Cycle Extended 3X! at Major US Fab Line

• Fab line has extended PM cycle from 60 to 180 days

• No evidence of erosion, leakage, mechanical damage or compression set after 180 days of service

• Equipment Platform — Novellus Concept Two SPEED

• Process — HDPCVD / STI

• Process Chemistry — SiH4, He, O2

• Cleaning Chemistry — NF3 plasma at 4000watts

• Seal Locations — slit valve door, inner gas manifold ring, MESC flange insert, Iso-poppet valve,turbo gate, dome lid

Case Report #6376 — PM Cycle Improved 2X! at Major European FabLine

• Fab line has extended PM cycle from 30,000 to >55,000 pairs of wafers

• No evidence of erosion, mechanical damage, compression set or deformation of the seallip

• Equipment Platform — AppliedMaterials Producer Low-k

• Process — PECVD / Black Diamond

• Process Chemistry — Trimethyl silane (TMS), O2

• Cleaning Chemistry — NF3 plasma via remote plasmasource

• Seal Location — VAT MONOVAT bonded door

Case Report #6441 — PM Target Exceeded at Major European ResearchCenter

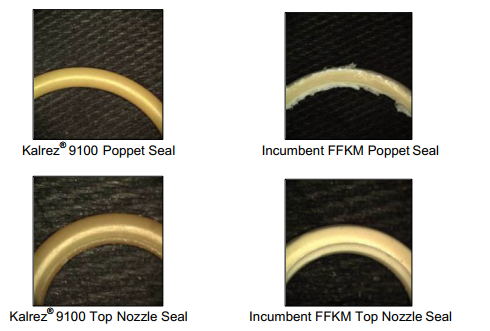

• No/minimal evidence of erosion or degradation after processing 5,000 wafers (Figure2)

• Research center is currently conducting testing to determine maximum practical seallife

• Equipment Platform — Applied Materials Centura Ultima

• Process — HDPCVD / STI

• Process Chemistry — SiH4, He, O2,

• Cleaning Chemistry — NF3 plasma at 3000watts

• Seal Location — roughing isolation valve poppet seal, top nozzle assembly o-ringseal

Case Report #6738 — PM Cycle Extended 3X! at Major US Fab Line

• Fab line has extended PM cycle from 400 to 1200 Rf hours

• No evidence of degradation or cracking after 1200 Rf hours ofservice

• Equipment Platform — Lam Research TCP-9600

• Process — Metal Etch and Resist Strip/Ash

• Process Chemistry — Cl2, BCl3, Water Vapor

• Cleaning Chemistry — O2 plasma (cleans ash deposits after every wafer)

• Seal Location – custom seal for slit valve opening

Case Report #10376 — PM Cycle Extended 2X! at Major AP FabLine

• Fab line has extended PM cycle from 27,000 to 54,000 wafers

• No evidence of erosion, cracking or compression set after processing 54,000 wafers

• Equipment Platform — Applied Material® Producer® SE

• Process — PECVD

• Process Chemistry — TMS, O2, He, Ar

• Cleaning Chemistry — NF3

• Seal Location — Lid Assembly

Warranty for Kalrez products

• Only applies to Dupont products distributed genuine in Vietnam.

• All Kalrez products are warranted if the machine fails due to manufacturer fault.

• For warranty and product maintenance, please contact Achilles, customer service phone number:098 469 4884(Ms. Duc).

• Achilles is the genuine supplier of products related to Kalrez DuPont.

• For retail/whole sale pricing, bulk ordering and product information advice please contact 098 469 4884(Ms. Duc) via info@achilles.com.vn or the website https://achilles.com/.

Tiếng Việt

Tiếng Việt

Reviews

There are no reviews yet.