DuPont™ Kalrez® AeroSeal™ 7797 perfluoroelastomer parts are a specialty black product specifically targeted for use in applications requiring high hardness/higher modulus properties. It offers outstanding thermal stability and compression set resistance and has excellent seal force retention properties. It also offers excellent resistance to HTS (High Thermo-Oxidative Stability) gas turbine engine lubricating oils and has excellent response to temperature cycling effects. Kalrez® AeroSeal™ 7797 has excellent mechanical properties and is well suited for both static and dynamic sealing applications. A maximum continuous service temperature of 325 °C (617°F) is suggested. Short excursions to higher temperatures may also be possible.

Typical Physical Properties

| Color |

Black |

| Hardness, Shore A (plied slabs) (test method ASTM D2240) |

90 |

| 50% Modulus, MPa (psi) (test method ASTM D1414 & ASTM D412) |

15.91 (2310) |

| Tensile Strength at Break, MPa (psi) (test method ASTM D1414 & ASTM D412) |

23.84 (3460) |

| Elongation at Break (%) (test method ASTM D1414 & ASTM D412) |

77 |

| Compression Set, %70 hrs.at 204°C (400°F) (test method ASTM D1414 & ASTM D395B) |

11 |

| Temperature of Retraction, Tr10 °C (°F) (test method ASTM D1329) |

-5 (23) |

| Maximum Service Temperature °C(°F) |

325 (617) |

Performance Features/Benefits

• Outstanding thermal stability

• Outstanding compression set resistance

• Excellent seal force retention properties

• Excellent resistance to high thermo-oxidative stability (HTS) gas turbine engine lubricating oils

• Excellent response to temperature cycling effects

• Excellent mechanical properties

• Lower coefficient of thermal expansion (CTE) versus other Kalrez® products thus minimizing the need to increase the free volume of the seal gland when upgrading from fluoroelastomers (FKM) to perfluoroelastomers (FFKM)

Resistance To Standard And HTS Gas Turbine Engine Lubricating Oils

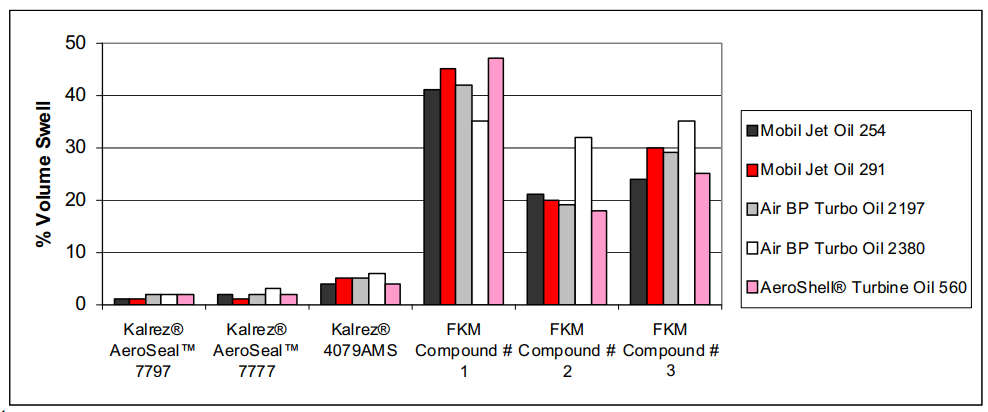

For many applications, low volume swell of elastomers is critical for proper equipment operation. Excessive swell can lead to material softening, “nibbling”, extrusion, etc., causing premature seal failure to occur. While other physical property testing may be needed to adequately define product performance in a particular application, volume swell has historically been used as an indicator of an elastomers’ chemical resistance to a particular fluid. Figure 1 shows the long-term volume swell for DuPont™ Kalrez® AeroSeal™ 7797, Kalrez® AeroSeal™ 7777 and Kalrez® 4079AMS versus three different types of FKM compounds in both standard and HTS (High Thermo-oxidative Stability) gas turbine engine lubricating oils after 1008 hours at 232 °C (450°F). Kalrez® AeroSeal™ 7797, Kalrez® AeroSeal™ 7777 and Kalrez® 4079AMS exhibited significantly lower volume swell versus the FKM compounds tested.

Figure 1. Long-Term Volume Swell In Standard* and HTS** Gas Turbine Engine Lubricating Oils

1008 hours at 232 °C (450 °C) — Oil Changed Weekly

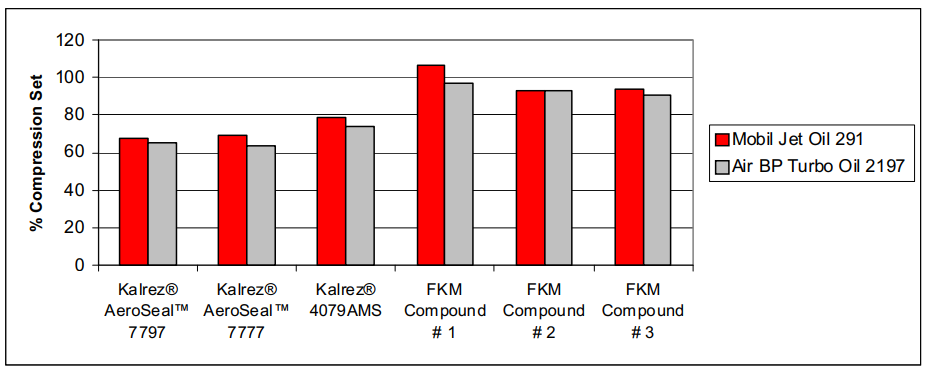

Figure 2 shows the long-term compression set properties of DuPont ™ Kalrez® AeroSeal™ 7797, Kalrez® AeroSeal™ 7777 and Kalrez® 4079AMS versus three different types of FKM compounds in HTS gas turbine engine lubricating oils after 1008 hours at 232°C (450°F). Kalrez® AeroSeal™ 7797, Kalrez® AeroSeal™ 7777 and Kalrez® 4079AMS exhibited better resistance to compression set versus the FKM compounds tested.

Figure 2. Long-Term Compression Set in HTS Gas Turbine Engine Lubricating Oils

1008 hours at 232 °C (450 °F) — Oil Changed Weekly.

Warranty for Kalrez products

• Only applies to Dupont products distributed genuine in Vietnam.

• All Kalrez products are warranted if the machine fails due to manufacturer fault.

• For warranty and product maintenance, please contact Achilles, customer service phone number:098 469 4884

(Ms. Duc).

• Achilles is the genuine supplier of products related to Kalrez DuPont.

• For retail/whole sale pricing, bulk ordering and product information advice please contact 098 469 4884 (Ms. Duc) via info@achilles.com.vn or the website https://achilles.com/.

Tiếng Việt

Tiếng Việt

Reviews

There are no reviews yet.