For Semiconductor Applications Involving High Intensity UV Radiation

Product Description

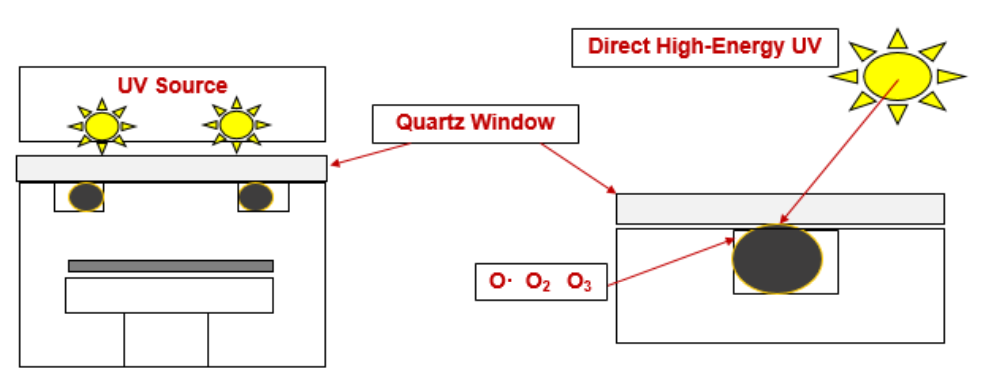

DuPont™ Kalrez® 8705 perfluoroelastomer parts are primarily designed for seal locations in the direct path of high energy ultraviolet (UV) radiation emitted from a conventional light source or from plasma. They also provide excellent resistance to high concentrations of damaging oxygen free radicals, and outstanding sealing functionality in high temperature vacuum applications. Their extremely low sticking force makes them ideal for sealing quartz surfaces like quartz windows in UV cure chambers and quartz tubes in photoresist strip equipment, without leaving undesirable residues. A maximum application temperature of 310°C is suggested. Ultrapure cleaning and packaging is standard for all Kalrez® 8705 parts.

Typical Physical Properties

| Color |

Black |

| Hardness, Shore A (plied slabs) (test method ASTM D2240) |

77 |

| 100% Modulus, MPa (psi) (test method ASTM D412) |

6.55 (950) |

| Tensile Strength at Break, MPa (psi) (test method ASTM D412) |

17.2 (2500) |

| Elongation at Break (%) (test method ASTM D412) |

180 |

| Compression Set, %70 hrs.at 204 °C (400 °F) (test method ASTM D395B và ASTM D1414) |

17 |

| Compression Set, %70 hrs.at 250°C (482°F) (test method ASTM D395B và ASTM D1414) |

24 |

| Maximum Service Temperature °C (°F) |

310 (590) |

Performance Features and Benefits

• Very durable against destructive UV rays

• Excellent resistance to damaging oxygen radicals

• Excellent (low) compression set properties

• Outstanding thermal stability

• Excellent seal force retention properties

• Ultra-low sticking on quartz surfaces

• Very low metals content

Suggested Applications

• Quartz Window Seal for UV Cure Chambers

• Quartz Tube Seal for Strip Chambers

Major 300mm Fab Chooses Kalrez® 8705 for its Great Value

A DuPont™ Kalrez® 8705 custom shape seal exhibited an outstanding balance of cost and performance in a Quartz Window Seal location of a LAM® Sola® xT ultraviolet thermal processing system. After 9 months of repeated, long (6-8 minutes) exposures to high intensity UV rays emitted while curing ultra-low k dielectric films, the seal was able to withstand the destructive UV radiation at very high temperatures (350-400oC on the pedestal) without experiencing any significant degradation or compression set. At the same time, the seal performed exceptionally well during the high temperature (150-200oC), long duration (8-10 minutes) ozone cleaning cycles of the UV cure chamber without showing signs of sticking or weight loss.

Warranty for Kalrez products

• Only applies to Dupont products distributed genuine in Vietnam.

• All Kalrez products are warranted if the machine fails due to manufacturer fault.

• For warranty and product maintenance, please contact Achilles, customer service phone number:098 469 4884(Ms. Duc).

• Achilles is the genuine supplier of products related to Kalrez DuPont.

• For retail/whole sale pricing, bulk ordering and product information advice please contact 098 469 4884 (Ms. Duc) via info@achilles.com.vn or the website https://achilles.com/.

Tiếng Việt

Tiếng Việt

Reviews

There are no reviews yet.