For Semiconductor Oxidation, Diffusion, ALD, and LPCVD Applications

Product Description

DuPont™ Kalrez® 8900 perfluoroelastomer parts are a black product for oxidation, diffusion, ALD, and LPCVD applications. It offers outstanding thermal stability, very low outgassing and excellent (low) compression set properties. Kalrez® 8900 parts exhibit excellent retention of physical properties at elevated temperatures, have excellent mechanical strength and are well-suited for both static and dynamic sealing applications. A maximum application temperature of 325°C (617°F) is suggested. Short excursions to higher temperatures may also be possible. Ultrapure post-cleaning and packaging is standard for all Kalrez® 8900 parts.

Typical Physical Properties

| Color |

Black |

| Hardness, Shore A (plied slabs) (test method ASTM D2240) |

76 |

| Hardness, Shore M (O-ring) (test method ASTM D2240 & D1414) |

85 |

| 100% Modulus, MPa (psi) (test method ASTM D412 & D1414) |

13.33 (1933) |

| Tensile Strength at Break, MPa (psi) (test method ASTM D412 & D1414) |

20.94 (3037) |

| Elongation at Break (%) (test method ASTM D412 & D1414) |

135 |

| Compression Set, %70 hrs.at 204 °C (400 °F) (test method ASTM D395B & ASTM D1414) |

8 |

| Compression Set, %70 hrs.at 250°C (482°F) (test method ASTM D395B & ASTM D1414) |

32 |

| Compression Set, %70 hrs.at 325 °C (617°F) (test method ASTM D395B & ASTM D1414) |

59 |

| Maximum Service Temperature °C (°F) |

325 (617°F) |

Features/Benefits

• Outstanding thermal stability

• Excellent (low) compression set properties

• Very low outgassing properties

• Very low moisture content

• Excellent retention of physical properties at elevated temperatures

• Excellent resistance to fluorine gas

Suggested Applications

• Quartz Tube Seals

• Plenum Seals

• Chamber Seals

• Fittings

• Center Ring Seals

Low Outgassing of Kalrez® 8900 parts

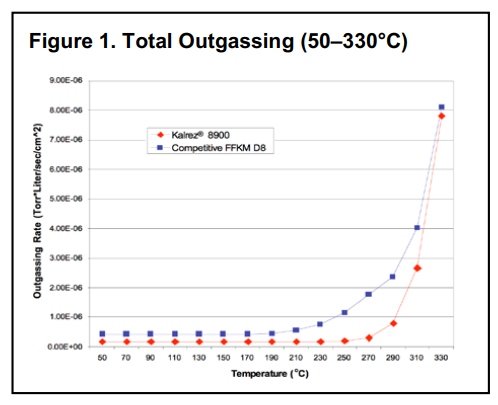

The crosslinking structure of elastomeric seals can become damaged as a result of exposure to high heat and temperature spikes. As a result, elastomeric seals can degrade causing outgassing to occur. Outgassing from sealing materials can be absorbed by the exposed substrate and affect the properties of the grown film. Figure 1 shows the outgassing properties of Kalrez® 8900 versus a competitive perfluoroelastomer.

Fabs Choose Kalrez® 8900 for Improved Performance

Kalrez® 8900 has been reported to significantly improve wafer production in semiconductor thermal process applications where aggressive gases are used during the cleaning cycle.

Case Report #12007 —Improved PM Performance 3x at Major US Fabline

• Exhibited less degradation than incumbent seals after 6 months in service

• Equipment Platform — Hitachi Kokusai Quixace®

• Process — Oxidation Diffusion

• Process Chemistry — H2, O2, N2, N2O

• Cleaning Chemistry — HCl

• Seal Locations — Complete Chamber O-ring kit

Warranty for Kalrez products

• Only applies to Dupont products distributed genuine in Vietnam.

• All Kalrez products are warranted if the machine fails due to manufacturer fault.

• For warranty and product maintenance, please contact Achilles, customer service phone number: 098 469 4884 (Ms. Duc).

• Achilles is the genuine supplier of products related to Kalrez DuPont.

• For retail/whole sale pricing, bulk ordering and product information advice please contact 098 469 4884 (Ms. Duc) via info@achilles.com.vn or the website https://achilles.com/.

Tiếng Việt

Tiếng Việt

Reviews

There are no reviews yet.