For Semiconductor Metal CVD Applications

Product Description

DuPont™ Kalrez 7075UP perfluoroelastomer parts are a black product targeted specifically metal CVD

applications. It offers outstanding thermal stability, very low outgassing and excellent compression set properties. Kalrez® 7075UP exhibits excellent seal force retention, has good mechanical properties and is well suited for both static and dynamic sealing applications. A maximum application temperature of 327°C (620°F) is suggested. Short excursions to higher temperatures may also be possible. Ultrapure postcleaning and packaging is standard for all parts made from Kalrez® 7075UP.

Performance Features/Benefits

• Outstanding thermal stability.

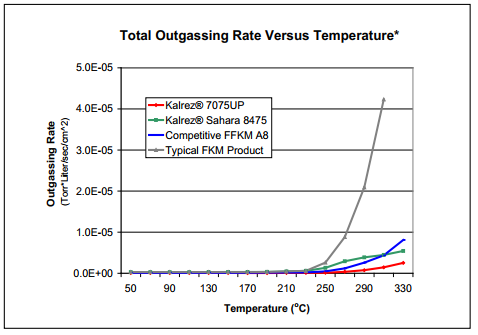

• Very low outgassing.

• Excellent resistance to ClF3.

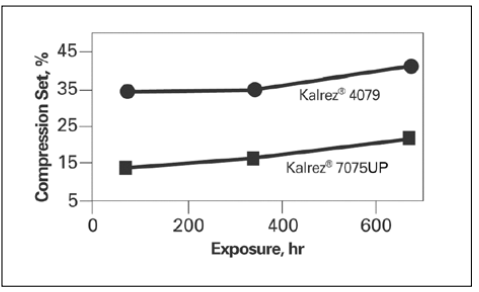

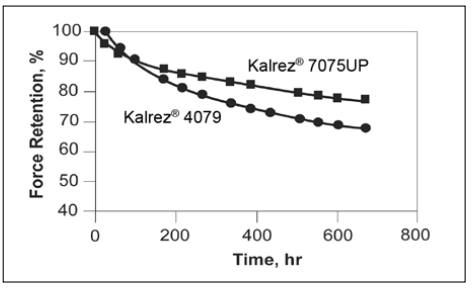

• Excellent (low) compression set properties.

• Excellent seal force retention properties.

• Excellent response to temperature cycling effects.

Typical Physical Properties

| Color |

Black |

| Hardness Shore A, (pellet) (test ASTM D2240) |

75 |

| Hardness Shore M (test ASTM D2240 & ASTM D1414) |

85 |

| 100% Modulus, MPa (psi) (test ASTM D412) |

10.54 (1529) |

| Tensile Strength at Break, MPa (psi) (test ASTM D412) |

17.26 (2503) |

| Elongation at Break (%) (test ASTM D412) |

148 |

| Compression Set, % 70 hr. at 204 °C (400°F) (test ASTM D395B & ASTM D1414) |

15 |

| Compression Set, % 70 hr. at 300 °C (572°F) (test ASTM D395B & ASTM D1414) |

19 |

| Compression Set, % 70 hr. at 325 °C (617°F) (test ASTM D395B & ASTM D1414) |

34 |

| Maximum Service Temperature °C (°F) |

327 (620) |

Compression Set/Seal Force Retention

Outgassing

High heat and temperature spikes can degrade elastomeric seals causing their crosslinking structure to become irreversibly damaged. In addition elastomeric seals can degrade under high temperatures causing outgassing to occur, thereby contaminating the process environment. The result is unscheduled downtime, or even worse, product loss. Figure 3 shows the outgassing properties of Kalrez® 7075UP versus Kalrez® 8475, Competitive FFKM D8 and a typical FKM product. Kalrez® 7075UP exhibited the lowest total outgassing rate.

Warranty for Kalrez products

• Only applies to Dupont products distributed genuine in Vietnam.

• All Kalrez products are warranted if the machine fails due to manufacturer fault.

• For warranty and product maintenance, please contact Achilles, customer service phone number:098 469 4884(Ms.Duc).

• Achilles is the genuine supplier of products related to Kalrez DuPont.

• For retail/whole sale pricing, bulk ordering and product information advice please contact 098 469 4884 (Ms. Duc) via info@achilles.com.vn or the website https://achilles.com/.

Tiếng Việt

Tiếng Việt

Reviews

There are no reviews yet.